In this follow-up article on digital twin, we discuss the data and IT challenges of implementing digital twins, the resources required for it, and a methodology for dealing with its complexities.

Navigating complexities in digital twin acquisition

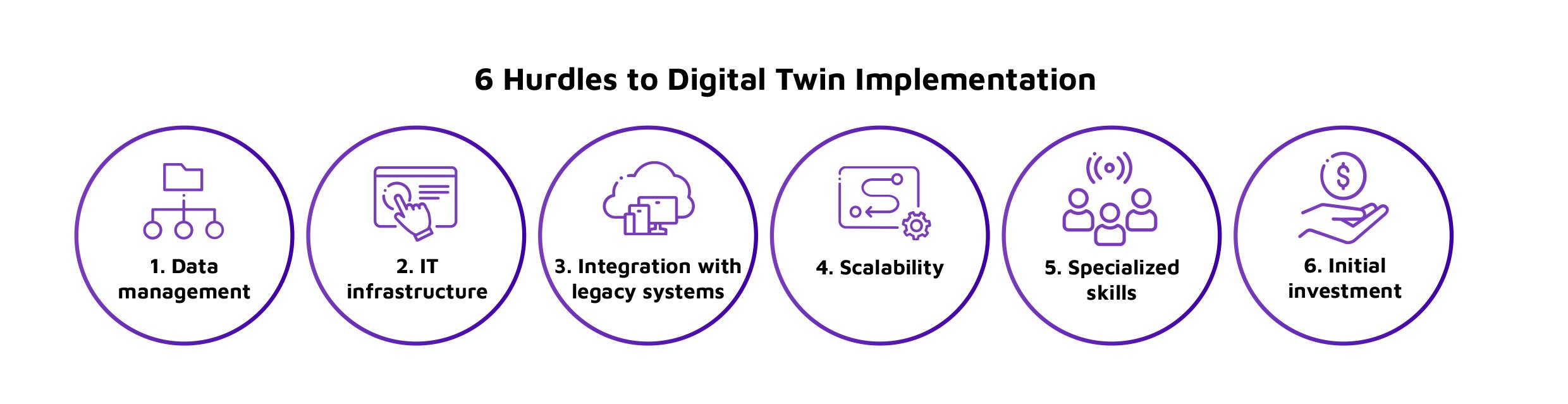

One of the foremost challenges in implementing digital twin technology is managing the sheer volume and variety of data required at the desired quality to power a digital twin. According to a research paper published in the International Journal of Information Management (2023), the complexity of integrating data and ensuring data quality are major hurdles. Inconsistent, incomplete, or inaccurate data can significantly diminish the effectiveness of a digital twin. Underestimating the complexity of data harmonization can lead to flawed decision-making based on the digital twin model.

The second piece of the puzzle is building the necessary IT infrastructure to support digital twin technology. Many organizations lack the advanced computational resources, like cloud computing, data lakes, edge devices, and other services such as internet-of-things (IoT) hubs, that are required for an effective digital twin implementation. Inadequate technological infrastructure can result in performance issues and limit the scalability and real-time capabilities of digital twins.

Then we have the challenge of integrating digital twin technology with existing legacy systems and processes that can be complex. Companies often face difficulties in aligning new digital solutions with their current IT infrastructure and operational workflows. Poor integration can lead to operational disruptions and data silos, undermining the effectiveness of the digital twin.

Scalability is also a major concern, especially as the organization grows and the supply chain becomes more complex. Most companies would start off with a proof of concept (PoC) or a proof of value (PoV) on a limited scope to prove the concept and value and secure more investment towards subsequent phases, however, often face major complexities when adopting the approach in scale. The digital twin must be scalable to accommodate changing business needs and increased data volumes, different specifications and parameters of production lines, warehouses, or product families. A digital twin that is not scalable may become obsolete quickly, requiring costly upgrades, replacements, or retirement.

Having the right talent in specialized skills and expertise, which may not be readily available within the organization, poses another key concern. The talent gap in areas such as data science, AI, and IoT is a significant barrier to move forward and incorporate this niche capability. Lack of skilled professionals can impede the development, deployment, and ongoing management of digital twin solutions. Hence, reliance on external vendors or partners may be deemed necessary, which derives extra costs.

The initial investment for digital twin technology can also be substantial, including costs for technology acquisition, development, integration, and training. Organizations must carefully consider the return on investment (ROI). Without a clear understanding of the potential ROI that would be driven by the business cases, organizations risk investing in technology that does not deliver the expected value outcome.

Blueprint and methodology for a successful digital twin implementation

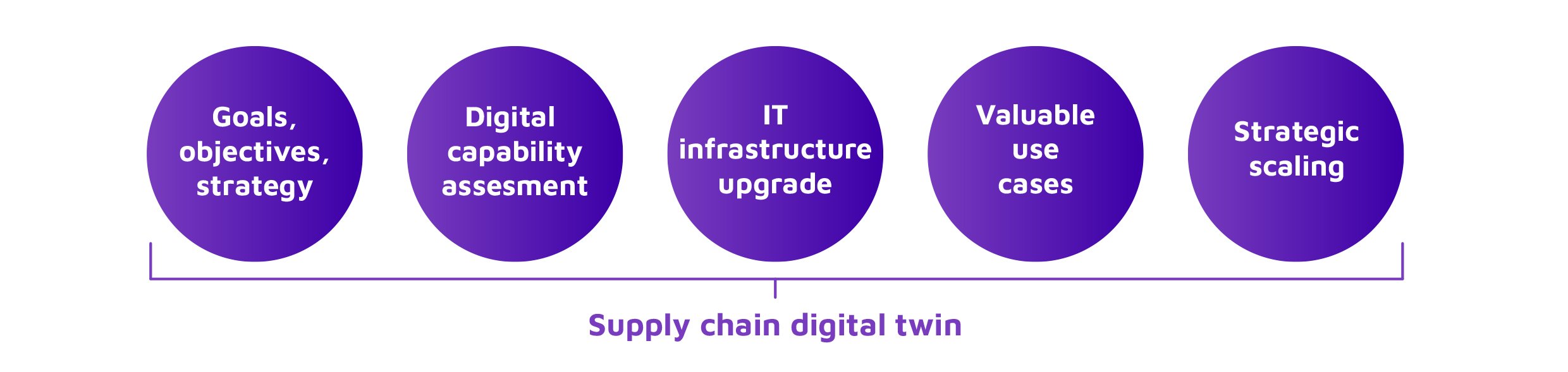

Below are five key pillars that serve as a starting point for directive guidelines for dealing with the complexity of implementing a digital twin:

1. Define the goals, objectives, and strategy.

Clearly articulate the goals of implementing a digital twin technology. It’s always recommended to start a top-down approach. This could involve enhancing supply chain efficiency, improving product quality, or driving innovation then start getting into the details, such as those affecting the manufacturing plant, storage facilities/warehouses, and network. Setting precise objectives ensures alignment with business strategies and makes value realization more attainable. This exercise could be started with an expert consultant.

2. Understanding your enterprise’s current capabilities and readiness.

Comprehensively assess the current operational and IT capabilities. This includes analyzing existing data infrastructures, software systems, and process workflows. Utilize frameworks like the Digital Capability Model (DCM) to evaluate the enterprise’s digital maturity. Understand best practices and benchmarks in digital twin implementation vs. your current state and the assessment outcome.

3. Uplift technological infrastructure and organizational structure.

Develop or upgrade the IT infrastructure necessary for digital twin implementation. This could involve investing in cloud computing, data lakes, IoT hubs, edge devices, and other technological advances deemed necessary based on the findings from the initial fit-gap assessment and benchmarks. Establish robust data governance policies and practices to ensure that high-quality data feeds the digital twin. This involves standardizing data formats, ensuring data accuracy, and integrating data from various sources.

4. Select the most impactful basket of use cases that prove value.

Start with a small-scale pilot project/PoC to test the digital twin in a controlled environment. This allows for identifying potential issues and making necessary adjustments before full-scale implementation while demonstrating the value to business stakeholders to empower the business case for continuous allocation of investment. Applying Agile project management techniques here is key to allow for flexibility, course correction, and iterative development based on feedback from stakeholders and findings from the pilot.

5. Strategically scale the digital twin use cases.

Gradually expand the scope of the digital twin implementation across the organization to other locations and categories. This should be done in phases, ensuring that each stage aligns with the overall business strategy and objectives, regional specifications and constraints, and individual parameters of operations among others, while also utilizing the reusability of assets wherever applicable. It’s recommended to start in the regions, sites, and with the product categories that would yield the highest ROI, but it’s also imperative to consider the whole portfolio to avoid false stars.

Future trends and how Lingaro empowers CPG innovation

As we stand at a new era in digital transformation, it is necessary to look ahead at the trends shaping the future of the CPG industry. Digital twin capability has become a critical technology and a main focus for the industry, including the following trends:

-

The use of AI and machine learning in digital twins will become more sophisticated, allowing for more accurate predictions and automated decision-making. Forbes’ 2023 technology forecast suggests that AI-driven digital twins could reduce supply chain forecasting errors of low-performers by up to 50% on an SKU level.

-

Blockchain technology is poised to revolutionize digital twins by offering enhanced transparency and traceability across the supply chain. A 2023 IBM report predicts a surge in blockchain integration, improving supply chain transparency by over 60%.

-

Digital twins are not only used to improve resilience in manufacturing but also in fulfillment. Many companies have already started to implement this capability in their warehouses to optimize the picking process (accountable for most of the operational costs) as well as set the right priority for the shipments. These tools are very often interconnected with warehouse management systems (WMS) to update transactional systems automatically.

With the many benefits of digital twin technology for the industry, we have been actively involved in integrating these future trends into our digital twin solutions. Lingaro’s approach focuses on five key areas:

-

Support our clients through the end-to-end journey toward a digital twin, from strategy, assessments, business case formulation and prioritization of use cases selection, development, and operationalization to servicing.

-

Develop cutting-edge digital twin solutions that incorporate AI, machine learning, and optimization models.

-

Harness the power of big data analytics to feed into our digital twins and provide actionable insights for decision-making.

-

Capture the growing importance of sustainability, with our solutions focusing on optimizing resource use, reducing waste, and lessening energy consumption.

-

Provide the right talent and expertise to ensure seamless development.

The future of digital twins in the CPG industry is marked by exciting technological advancements and an increased focus on efficiency, sustainability, and innovation. As we continue to evolve our offerings, the intersection of technology, business, and practical application remains our guiding principle, ensuring that our clients are equipped for the challenges and opportunities of the future.