Opportunities in manufacturing and logistics come with big challenges. With today’s market changes and technology advancements, leaders need to be more resilient and “smarter.” Experts from Lingaro’s supply chain analytics (SCA) practice share insights on how analytics and AI can help businesses get the most out of new innovations in logistics, warehousing, transportation, and manufacturing.

The ‘antifragile’ supply chain: Boosting resilience in logistics

Logistics costs — labor, fuel, electricity, energy, and transportation — are going up. Along with constant market disruptions, they make managing warehousing, transportation, and logistics difficult. A 2023 Gartner® survey found that 89% of chief supply chain officers (CSCOs) expect these uncertainties to stay. Also, 63% of think that exposure to these uncertainties will lower their revenues.

This is why an “antifragile” supply chain will be key for logistics in 2024. Antifragility means achieving the best outcomes while learning and adapting to change. It uses uncertainties for growth rather than just avoiding them.

Konrad Rosiński, a lead consultant at Lingaro’s SCA practice, said, “Antifragility in supply chain management means investing in digital tools to quickly adapt to disruptions. This is especially true in logistics. Costs and needs evolve rapidly due to changes in supply and demand, consumer preferences, competitor behaviors, and geopolitics.”

For logistics, becoming more antifragile or resilient means gaining full visibility into the supply chain. “Large companies need to assess their end-to-end logistics process for comprehensive solutions, not just parts to optimize,” said Konrad. A McKinsey study showed that companies with better visibility across their supply chain are twice as likely as others to prevent problems caused by disruptions.

This visibility lets CSCOs monitor and manage their supply chain better. “In resource management, a CPG or manufacturing company can adjust labor based on seasonality to scale up or shift workforce as needed. The workforce is not just a cost, but an asset that can adapt through various business cycles. In warehousing, layouts driven by demand can change in real time. For example, fast-moving items are placed closer to packing areas, staging zones, or loading docks during busy times to cut down on distance and time for pickers,” Konrad explained. A system for optimizing warehouses can plan out task schedules, decide when each task starts and ends, and see which are most critical.

Another case is in transportation. If a region suddenly needs more trucks due to a spike in demand, they could use a system that automatically reroutes vehicles from areas that are less busy. It can also be used to keep the use of fleets in sync with the volume of products, routes, and optimal mix of owned and third-party trucks. It can also predict repair and maintenance to keep vehicles ready.

-1.png?width=3900&height=2232&name=MicrosoftTeams-image%20(8)-1.png)

Figure 1. A sample dashboard that provides visibility into crucial KPIs and metrics for logistics

These strategies all come down to data. Konrad emphasized, “Being both resilient and antifragile means having the right data to adapt and improve constantly. For global companies, this means looking for ways to save and enhance logistics through solutions that make good use of data.”

Indeed, IDC forecasts that by 2026, 75% of supply chains will invest in systems that link supply chain planning and fulfillment more closely. A recent study on third-party logistics (3PL) found that both shippers, carriers, and forwarders as well as 3PL providers see advanced analytics as one of the top technologies for their future. AI and machine learning will also be key: AI in warehouses is expected to grow tenfold by 2028. By 2026, 55% of top manufacturers in Forbes Global 2000 will redesign their supply chains with AI for better efficiency and sustainability.

Konrad also mentioned various projects by Lingaro’s SCA practice for global CPG companies. These projects include solutions for warehouse operations that manage space and resources efficiently, like labor, equipment, and task scheduling. They review manual warehouse operations then suggest automation levels to boost efficiency, lower costs, and improve service.

Another is in transportation, where advanced analytics (AI and other techniques including statistical and predictive forecasting) is used to merge various sources of data to plan capacity, optimize routes, work out costs, and perform simulations. The SCA practice also creates solutions to manage logistics costs effectively by analyzing variables like forecasted vs. actual expenses, cost to serve, cost per unit, and auditing freight bills.

“Data is crucial to resilient or antifragile logistics, but the right mindset is vital to achieve it,” Konrad said. “Company issues can prevent taking full advantage of uncertainty. Resilience or antifragility involves a major change in how CSCOs develop and implement their strategies.”

Konrad advises a long-term view on ROI. This means looking at technologies and initiatives that, despite initial costs, offer significant savings and efficiency improvements over time. Indeed, Gartner’s research on antifragile supply chains shows that in uncertain times, assessing investment values can be 4.5 times more effective in improving revenues. Likewise, focusing on comprehensive supply chain planning in such times is 2.5 times more likely to lead to better financial results.

Accelerating digital transformation with smart manufacturing

Disruptions in the global supply chain also affected manufacturing, which led businesses to cut costs and reduce waste. These make digitalization more important.

Smart manufacturing, which involves the use of automated, connected, and intelligent machines and systems, will play a bigger role in improving manufacturing. A survey by Gartner® found that 80% of top executives list business growth, cost efficiency, and digital transformation as their main goals for investing more in digital technologies for manufacturing.

Yassin Ibrahim, head of manufacturing and inventory at Lingaro’s SCA practice, explained, “To better handle disruptions and be more resilient, companies need to gather, centralize, and analyze machine and supply chain data. AI can help by quickly turning this data into useful actions — in real time, if necessary."

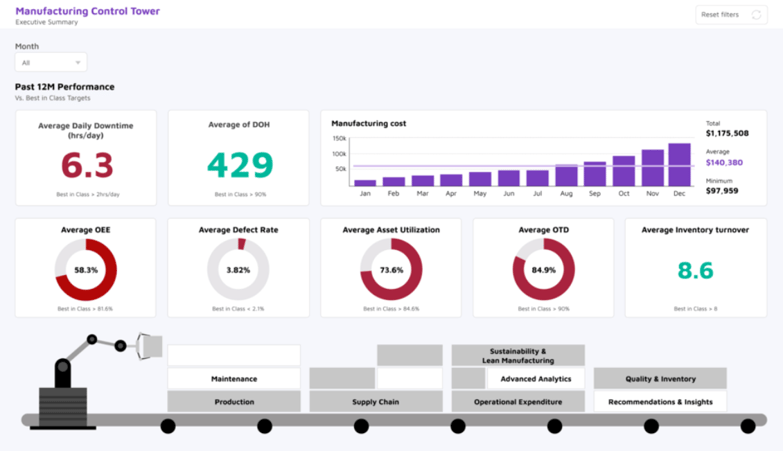

Figure 2. A sample manufacturing control tower

Data and analytics is key to digital transformation. Manufacturing control towers, digital twins, and advanced analytics help gain insights, make improvements, and run simulations to better plan and manage manufacturing processes. AI and machine learning (ML) can support other technologies like cloud computing, computer vision, the internet of things (IoT), and manufacturing analytics for quality assurance, anomaly detection, and predictive maintenance.

Connectivity improvements will work together with analytics in transformation. Cloud computing will support different AI-powered apps and data transformations for control towers or digital twins. McKinsey predicts that about 70% of businesses will use hybrid and multicloud solutions, while Gartner® expects that over half will use flexible and specific industry cloud platforms. Faster LTE speeds via 5G networks will enable faster sensor data collection and real-time processing in IoT and industrial IoT (IIoT) implementations. Lingaro’s SCA practice, for example, works with CPG and FMCG manufacturers on their digitalization efforts. These include building solutions via digital twin technologies and activating use cases for their cloud data.

All these will require new systems, ways of working, and investments. Leaders must ensure that their organization is ready for these changes to avoid costly disruptions. In fact, in 2024, 50% of manufacturers will focus on digital literacy to support digital transformation and increase the adoption of new technologies across their business. The right resources, digital skills, and capabilities will enhance productivity, lower costs, and improve operations.

“As new AI technologies emerge and as enterprises become more mature in their data strategy and IT infrastructures, businesses see the benefits of digital transformation, and why it’s necessary to stay competitive in these challenging times,” Yassin noted.

Industry 4.0 is evolving fast. As new technologies and market disruptions change how products are manufactured and transported, leaders must also change their strategy. Analytics, digitalization, automation, and AI will help businesses get ready for the future they want to achieve.