Inventory optimization is a critical element in managing company assets. On one hand, it can be treated as a cost meant to reduce other expenses, such as addressing obsolete inventory or excess stock. On the other hand, it can also be used as an essential component in conducting company operations and helping to fulfill strategy.

A common misunderstanding is that the inventory kept on hand is undesired and needs to be reduced as much as possible. In this article, we’ll dive deeper into inventory management and the key role that stock plays in the whole supply chain.

Inventory optimization: Functions of stock in the supply chain

Understanding what happens to inventory and where it plays a role in the supply chain can make a company’s operations more efficient. Businesses maintain stock for many different reasons, so we can distinguish different types based on their functions.

The most important inventory functions to consider are:

-

Decoupling stock

-

Cycle stock

-

Pipeline stock

-

Buffer stock (safety stock)

Decoupling stock detaches a process from another. Manufacturing a product typically requires several steps, usually in a sequence. Manufacturing equipment has different processing capacities — some may be faster, while others may take more time to process the same number of jobs. Equipment may also encounter a failure. If this happens, all upstream processes have to wait until the failed equipment is back up and running. The function of this inventory is to help smoothen the flow between process steps and minimize the impact of process variability.

Cycle stock, or sometimes referred to as working inventory, is the result of ordering or manufacturing materials in batches. A company does not procure or buy all materials at one go. In most cases, they also do not order one unit at a time. Usually, the ordering or manufacturing processes are performed in batches and lots, generally larger than expected, and demanded to meet the agreed order size (e.g., minimum order quantity, minimum production run, full truckload). Firms prefer batch ordering because, for example, they derive benefits from economies of scale.

Pipeline stock is inventory in transit (in a truck, ship, rail, etc.). The ordered materials are not received instantaneously just after sending an order to the vendor. There is a delay between placement and receipt due to the distance and time between the supplier and the company. The longer the lead time, the higher the pipeline inventory level will be.

Buffer stock, also known as safety stock, is maintained to manage uncertainty (variability) both from a supply and demand perspective. Buffer inventory reduces the probability of running out of stock. The higher the variability in the supply chain, the higher the level of buffer stock will be. Along with the increase of the desired service level, you can also expect an increase in buffer stock.

Strategies for inventory optimization

Inventory management can help optimize operations, lower costs, and improve customer service. However, properly implementing it requires businesses to understand how much stock should be kept or reduced, in order to minimize excess inventory or obsolete stock.

There are a number of factors involved that makes these decisions quite complex. It can be challenging to find a good balance between executing the company’s short- and long-term objectives of inventory-related cost reductions and efforts to increase cash flow. Thanks to advanced analytics, these decisions can be supported by solutions that streamline processes to find the right balance and avoid stockouts, slow-moving inventory, and excess stock.

When employing inventory optimization strategies, companies should, among others, recognize these key improvement drivers:

-

Inventory visibility

-

Demand variability reduction

-

Supply variability reduction

Inventory visibility

Understandably, you can’t control what you can’t measure. When it comes to inventory management processes, inventory visibility is a critical place to start. Constantly changing data coming from multiple sources like enterprise resource planning (ERP) and other planning systems requires one central information point to help make rapid decisions on both strategic and operational levels.

To be up to date on these changes, it is necessary to have full visibility into:

-

The current level, trend, and future inventory projection in real time.

-

Different points of view on the same inventory, e.g., volume (planning), value (financial), cube (logistic and warehouse), etc.

-

Different aggregation levels, e.g., geography, plant, warehouse, distribution center, business unit, etc.

-

Item status (active, on-hold, rejected).

-

Item life status (active, phased out items, obsolete inventory, excess stock).

With good inventory visibility, companies can:

-

Precisely discover and select the right points for improvement.

-

Manage operations more easily and efficiently.

-

Access reliable reporting with constant updates about progress towards strategic, operational, and financial goals related to inventory.

Supply and demand variability reductions

Variability reduction is the holy grail of all supply chains and, at the same time, the biggest challenge when it comes to improvements. As mentioned before, a higher variability in the supply chain means a higher buffer stock level.

We can see two sources of variability:

-

Supply variability reduction: Unpredicted lead time both from external vendors and internal manufacturing processes

-

Demand variability reduction: Unpredicted demand and involves pure forecasting process performance

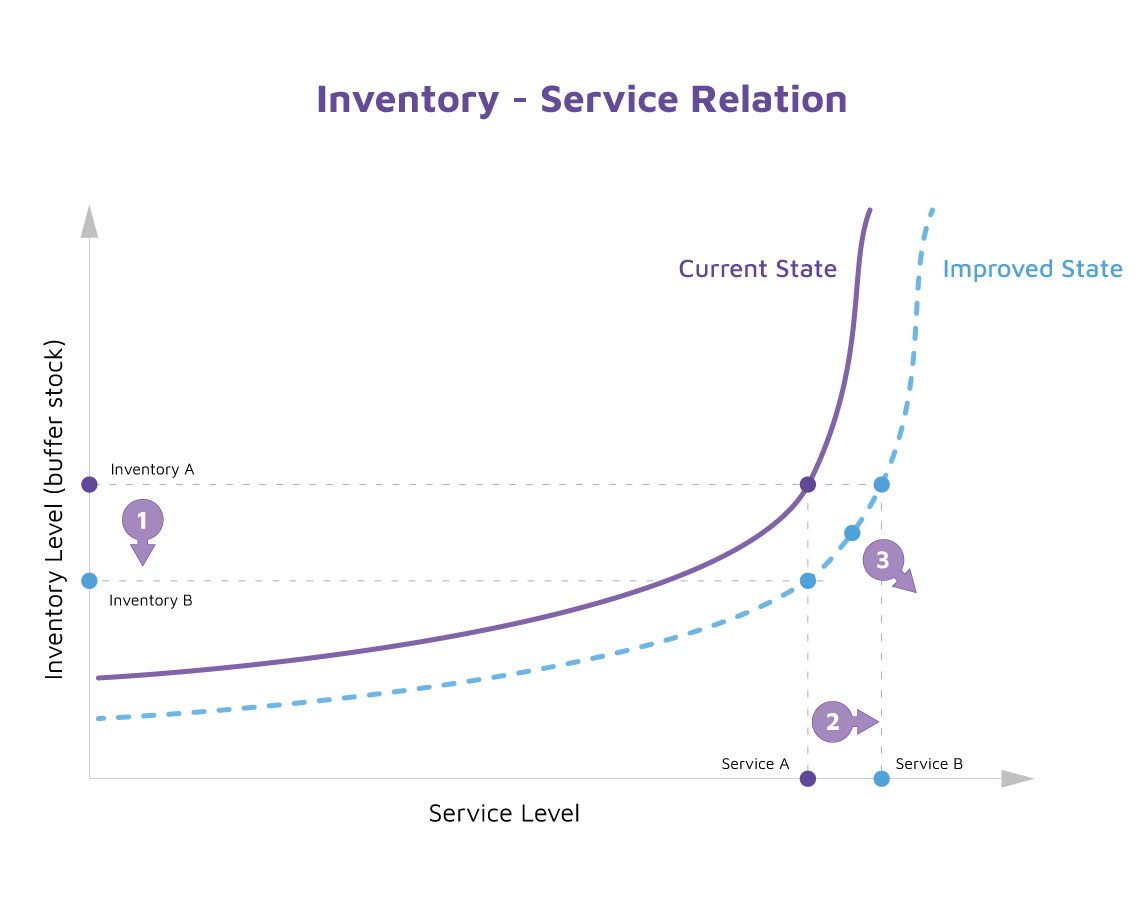

The following figure is a good illustration of how variability affects inventory levels. Let’s assume a certain variability in the supply chain system and represent the current relations between inventory and service level with the solid line.

Some buffer stock (Inventory A) must be kept in order to achieve the service level (Service A). Along with variability reduction, the relationship between the inventory and service level (dashed line) will change.

Now, three options are available:

-

Keep the same service level (Service A) by keeping less buffer stock (Inventory B).

-

Increase the service level (Service B) by keeping the same buffer stock as before (Service A).

-

Adopt a balanced approach that reduces the buffer stock, and at the same time, improves the service level.

A visualization showing how variability affects inventory levels

Achieving improvements in inventory management

Demand forecasting processes can be improved by applying the right processes and advanced analytics solutions. Improved forecast accuracy will also have an impact to reducing excess stock or obsolete inventory and other costs associated with the disposal and sale-off plans for unproductive inventory.

On-time and in-full delivery can be improved by using the right vendor measurement techniques and tools. Among inventory improvement, supply variability reduction can positively impact cost reduction in other areas like manufacturing, warehousing, and transportation.

Inventory optimization through inventory visibility

Proper inventory management can change and streamline a company’s operations. Improving inventory management can be initially difficult, especially in the today’s dynamically changing environment. However, a good partner like Lingaro with experienced specialists and a track record of successfully delivered projects can be a great support to make its implementation easier.

Lingaro shares broad experience and best industry practices gained during many supply chain related projects. Our specialists, both in technology and business, can bring the right process and tools for faster progress and better control over the supply chain.

Contact one of our specialists to find out how to turn your company’s inventory into strategic assets that secure services and support business operations in fulfilling long-term strategies.